DDLock - Dema Double Lock: Double way to win together

DDLock, is the new technology developed by our engineers’ team to reach the higher and higher quality standards that are requested from the market. Dema Double Lock avoids the possibility to get even only the smallest defect on the stator stack.

Sometimes the polar expansions tend to rise up and that can lead to mechanical defects and electrical functional problems. In order to prevent those inconveniences in the further production process, Dema developed two different and effective ways: Backlack DDLock and Glue DDLock.

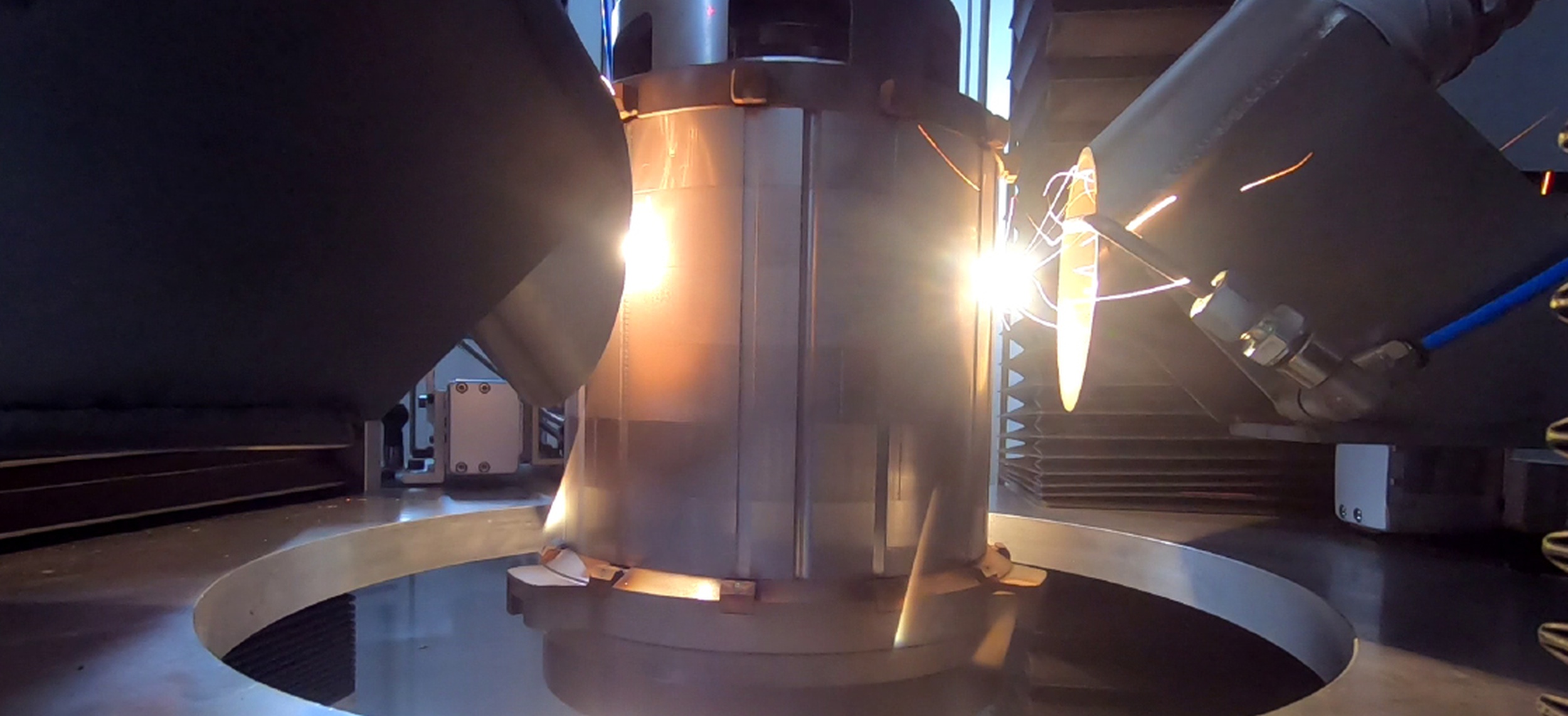

The first solution (welding + Backlack) forsees the use of Backlack laminations portions to the stack extremities. At first the stack will be laser welded and then it will be further compacted thanks to the Backlack glue activation using induction heating or another thermal process.

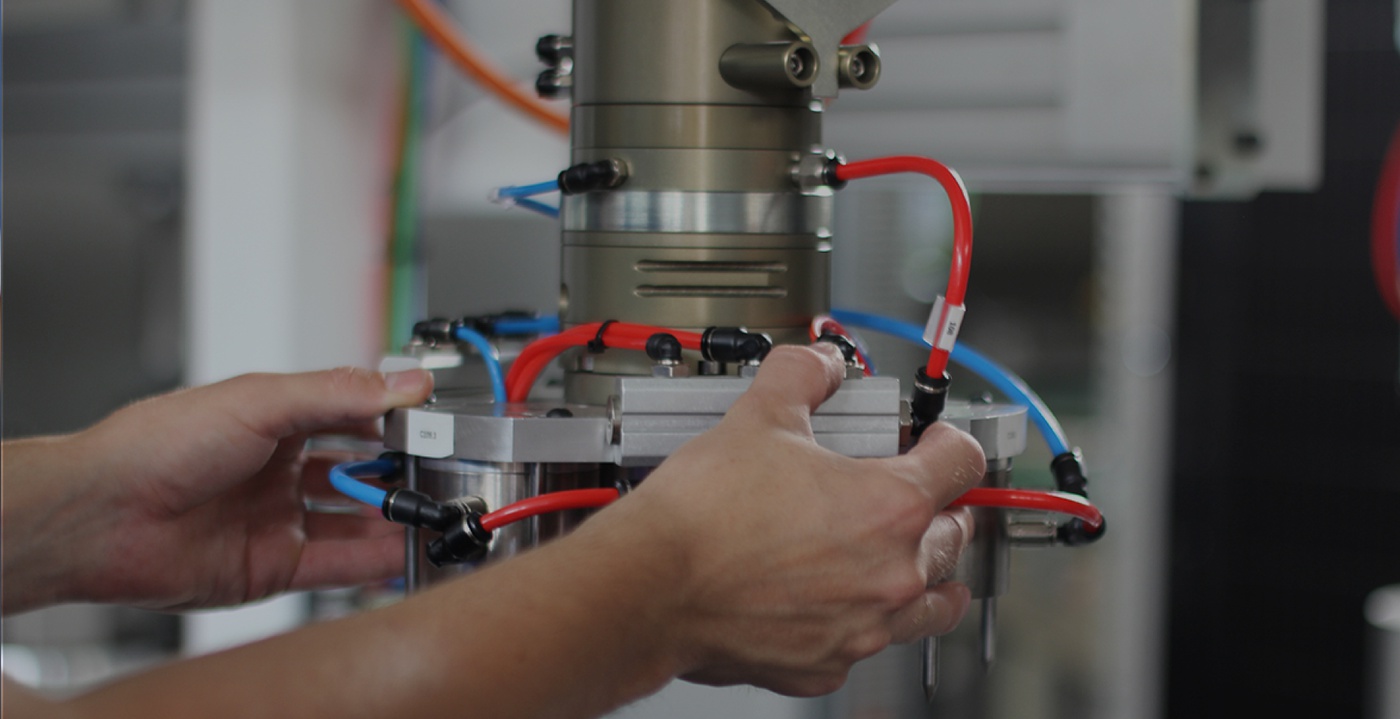

The second option (glue + welding) permits to obtain the same very good result but using traditional electromagnetic laminations. The external portions of the stack will be put into a glue dosing station that will distribute the glue uniformly. This will immediately compact the polar expansions. After that, the stack will be laser welded in order to guarantee the features of the finished stack.

The new Dema DDLock technology by means of a double joining process, permits a double security on the final result thanks to the union of already consolidated and successful technologies.

DDLock runs on two parallel streets that go to the same winning objective.

After the first online presentation of the DDLock, we had a very positive answer and we noticed a great interest from the technicians in the field. That is a confirmation that we’ve individuated a solution for an unsolved problem.

If you are interested too, please contact our office to go deeper in technical details and in the advantages that DDLock can bring to your activity.